Page last updated 30/08/2018

There are a range of designs of biogas plant that are being used in different places.

The designs used in large numbers are based on two concepts:

1.

The floating drum biogas system, as developed by KVIC in India;

2.

The underground dome plant, as developed in China.

Both designs use a cylinder built from masonry in a hole in the ground. There are variations

of both concepts.

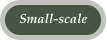

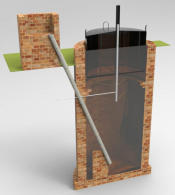

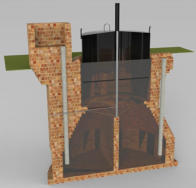

A standard KVIC plant is a deep brick lined cylinder in a hole in the ground. A mixing pit

allows animal dung and water to be mixed into a slurry before it is allowed to flow through a

cement pipe into the main digester. The spent slurry is allowed to overflow from a channel

through the rim at the top of the cylinder. The gas collects in a steel drum that floats in the

slurry and moves up and down as gas is generated and used. In some plants, an annulus is

made around the top section of the cylinder, filled with water so the drum can float.

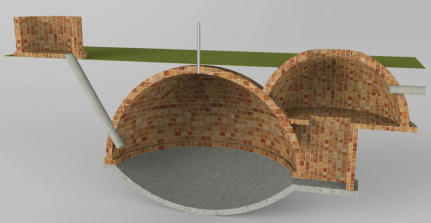

In Nepal, there was a requirement for plants that did not require such a deep hole. A

tapered hole, of the same overall volume, was used. The inlet and outlet pipes ran vertically

to each side of the enlarged hole base. A central dividing wall was used to ensure the slurry

flowed between the inlet and outlet, without taking a short cut.

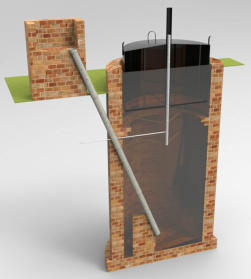

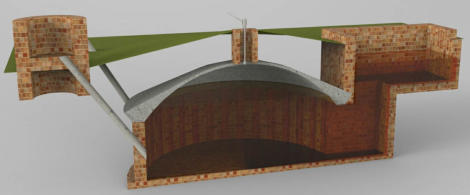

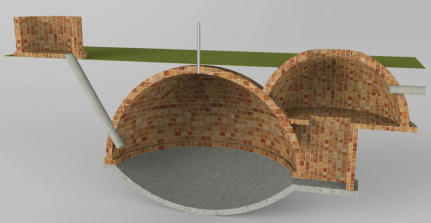

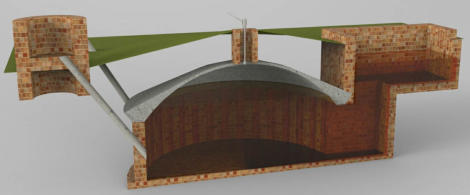

The underground dome plant uses a fixed dome made from masonry (bricks or concrete)

over the digester. They have a mixing pit at one side and a slurry reservoir at the other. Gas

is stored in the fixed dome, using the “displacement principle”.

The processes involved in generating biogas and good quality, smell-free compost from

biomass are described in both the books and summarised under Technology.

Technical aspects

KVIC design with floating steel drum

Floating drum design used in Nepal

Fixed brick dome biogas plant

(Deenbandhu)

Fixed concrete dome biogas plant

(GGC 2047)

Page last updated 30/08/2018

There are a range of designs of biogas plant that are being

used in different places.

The designs used in large numbers are based on two

concepts:

1.

The floating drum biogas system, as developed by KVIC

in India;

2.

The underground dome plant, as developed in China.

Both designs use a cylinder built from masonry in a hole in

the ground. There are variations of both concepts.

A standard KVIC plant is a deep brick lined cylinder in a hole

in the ground. A mixing pit allows animal dung and water to

be mixed into a slurry before it is allowed to flow through a

cement pipe into the main digester. The spent slurry is

allowed to overflow from a channel through the rim at the top

of the cylinder. The gas collects in a steel drum that floats in

the slurry and moves up and down as gas is generated and

used. In some plants, an annulus is made around the top

section of the cylinder, filled with water so the drum can float.

In Nepal, there was a requirement for plants that did not

require such a deep hole. A tapered hole, of the same overall

volume, was used. The inlet and outlet pipes ran vertically to

each side of the enlarged hole base. A central dividing wall

was used to ensure the slurry flowed between the inlet and

outlet, without taking a short cut.

The underground dome plant uses a fixed dome made from

masonry (bricks or concrete) over the digester. They have a

mixing pit at one side and a slurry reservoir at the other. Gas

is stored in the fixed dome, using the “displacement principle”.

The processes involved in generating biogas and good quality,

smell-free compost from biomass are described in both the

books and summarised under Technology.

Technical aspects

KVIC design with

floating steel drum

Floating drum design used in Nepal

Fixed brick dome biogas plant

(Deenbandhu)

Fixed concrete dome biogas plant

(GGC 2047)